Energy Optimization Evolves: 10 Years Later, the Energy Savings Continue to Add Up

With all the focus on energy-efficiency and the drive to reduce carbon emissions in buildings through design and technology investments, it is easy to overlook the fact that significant energy savings can be achieved as a byproduct of well-performing building systems. As equipment ages, as minor components fail, as the seasons change, and as space utilization evolves, there are steps building engineers can take to prevent the performance degradation typical of building equipment and systems over time. Yet without a clear plan in place for taking these steps, they are often forgotten or ignored until more costly maintenance or replacement is needed.

This was the premise behind the Energy Optimization program for a national health system back in 2010. When the health system contracted EH&E for a pilot program at one of its hospitals, it was with the goal of implementing low-cost improvements to ensure consistent building system performance. By bringing systems back to their as-designed performance requirements (or in many cases current performance requirements), the facility aimed to reconcile intended performance and inherently reduce its over-all energy use and associated utility costs.

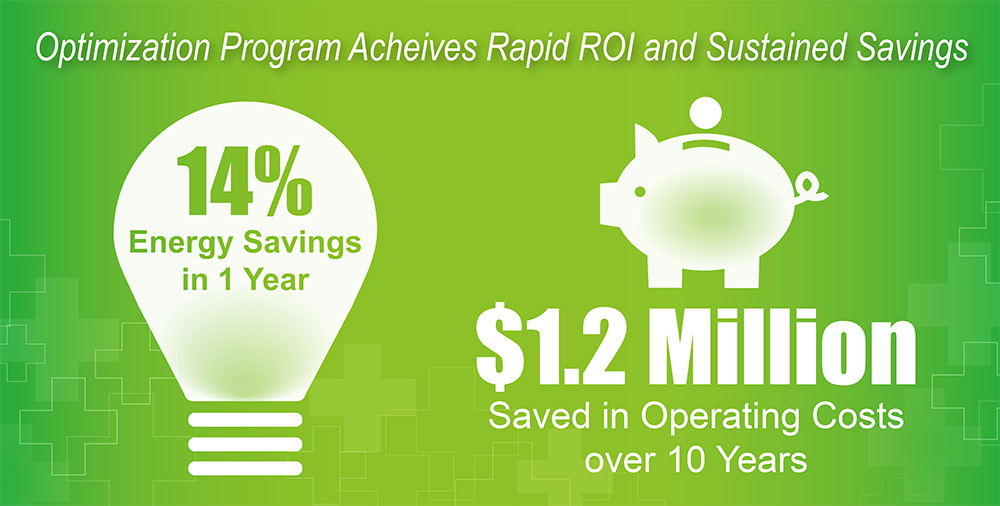

That goal has paid off. In its first year, the project achieved 14% energy savings (MMBTU) and a 10% cost reduction. More than a decade later of consistent improvements, the hospital has seen an estimated cumulative savings of over $1.2 million in operating costs. That’s a striking enough figure on its own, yet only begins to hint at what this program has accomplished.

As this energy optimization program has rolled out across the health system’s nationwide footprint, it’s helped drive millions in cost savings. However, it’s also created healthier spaces and driven improvements in building documentation that supported an adaptable COVID response. These energy efficiency improvements have also laid the groundwork as a pivotal first step closer toward the system’s pledge to achieve a 50% reduction in emissions by 2030 and net-zero emissions by 2050.

National footprint leads to changes in approach

The pilot project’s success was the result of an analysis of the HVAC system and hospital operations to determine the most impactful low-cost improvements. They included simple adjustments, such as taking certain air handlers/variable-air-volume boxes and associated exhaust/return fans offline for four to eight hours during non-demand periods, replacing leaking valves, and repairing poorly functioning equipment that was found to have inefficiencies.

Simple improvements remain the focus of the energy optimization program, yet in some ways the program has had to evolve. Because it is now implemented in 30 facilities across the country, this assessment and energy analysis process must account for regional seasonality differences. In regions where there are drastic changes in temperature throughout the year or even the day, facilities can reduce energy usage simply through adjusting the sequence of operations. Areas with more consistent climates may require more in terms of minor repairs or demand-based operating schedules.

The program has also evolved to account for differences in the age of the targeted facilities and the sophistication of their building controls. Hospitals with robust building automation systems often are able to make minor control changes that drive significant energy reductions without sacrifice to other parameters, such as comfort. Facilities with weak or no automation may require a different approach, often driven by repairs, such as replacing dampers or valves, or minor investments, such as HVAC time clocks that allow for simple control options. No matter how sophisticated the facility, however, there are often opportunities to adapt.

Despite the national focus, the EH&E team continues to revisit the hospital that was the focus of the pilot study and facilities targeted in the program’s earliest stages for regular “tune-ups.” This periodic review allows the energy optimization team to implement new strategies while also updating equipment based on changing space utilization. It also helps ensure that early energy-saving measures put in place are maintained to ensure a lasting impact. As maintenance team’s respond to in-the-moment needs, it is often easy to eliminate an energy saving measure without realizing it. Within the energy optimization process, it is often possible to adjust parameters to better account for user requests in alignment with energy savings. To truly be effective, optimization must be a continuous process.

Improvements that go beyond energy

Maximum system performance and energy reductions may be the goal of these optimization projects, but over time the process has proven to have a number of additional advantages. One of those benefits is simply the process of creating the documentation needed to support the analysis of HVAC and other systems.

Improving equipment performance begins with a clear understanding of how equipment is intended to operate within a given space and a baseline for how it is performing today. This requires documentation, which may include equipment lists, zone maps that indicate where ventilation is coming from and what it serves, and facility drawings, among other information. This documentation provides a guide of sorts that makes it easier to ensure that systems are brought back into appropriate performance parameters following any future changes.

Of course, if this documentation is not provided during construction handoff, it can be an overwhelming task to recreate this information. It’s why lack of documentation has remained a pressing challenge for so many facilities. However, this energy optimization program begins with the creation of facilities documents that provide a wealth of benefits to hospital teams.

Documentation provides facilities team with a reference for a better understanding of their buildings. While energy optimization focuses primarily on low-cost measures, this documentation can also help facilities understand the potential impact of future capital investments. It can help improve maintenance and maintenance schedules and streamline the passage of information in the event of staff turnover. Having reliable facilities documents available also made it easier to return to appropriate ventilation and pressurization schemes following COVID-driven adjustments.

Energy optimization supports strategic goals

Many facilities managers are aware they may have opportunities to improve their building’s performance. Devoting resources to these tasks, however, becomes much easier with the backing of the C-suite and a clear plan for how to reduce costs through this work. For our client, this initially meant moving forward with a project fee that was structured so that payments would come from realized project savings as opposed to operational budgets.

As utility rates increase around the country today, these utilities cost savings make an even more favorable financial case for energy improvements. In its September 2022 forecast on electricity costs, the U.S. Energy Information Administration projected the average price of electricity for commercial consumers across the U.S. will reach 12.1 cents/kWh in 2022 and 12.46 cents/kWh in 2023, up from 11.27 cents/kWh in 2021 and 10.59 cents/kWh in 2020.

Regions facing the highest energy costs will see a far quicker payback on their investments. For this nationwide project, payback periods have ranged from 9 to 12 months in the Northeast, to two years in other regions. Overall, the optimization program generates an estimated minimum of $2.5 million in annual revenue to the bottom line across the healthcare system’s portfolio. Many hospitals are able to reinvest their savings into larger-scale improvements that drive down energy usage and greenhouse gas emissions, thus helping health systems meet their strategic sustainability objectives.

However, there’s an even more powerful case for these programs today. We’ve seen clear evidence thanks to the COVID pandemic that high-performing systems are simply healthier and more comfortable.

Meeting team and energy demands

We’ve seen time and again that an energy optimization program can help facilities professionals better do their job by accessing information that may not be readily available. With all of the intense demands upon these professionals, there rarely is enough time and manpower to dive into systems that appear to be working fine. But with the support of a consultant who is able to make this deep dive into your facility’s energy usage and system operation, you can gain powerful tools to help you better care for your building and its patients.

If you’re ready to develop a strategy for optimizing your building systems, contact EH&E today.

Subscribe

to our blog

"*" indicates required fields