Hospital Achieves Energy Optimization by Fine Tuning Existing HVAC Systems, Saving more than $400,000 Annually

EH&E conducts comprehensive energy- savings study, identifying multiple Energy Conservation Measures

A New Hampshire hospital wanted to be proactive in its commitment to reducing energy emissions and operational costs. The challenge was how to achieve this in the face of financial and resource constraints typical to most hospitals.

EH&E was able to offer an approach to energy optimization that addresses these realities. Our program relies on fine tuning existing systems – not major capital expenditures – and utilizes a pay-for-performance contract model, significantly reducing risk and allowing the hospital to confidently move forward with meeting their energy-reduction goals.

Collectively, the implemented measures reduced energy use by more than 15.9 million kBtu per year, including 1.35 million kWh of electricity and 112,700 therms of natural gas, for an annual cost savings of approximately $400,000. If maintained, these improvements are projected to generate more than $4 million in cumulative savings over the next decade.

The seven-story, 415,000 square-foot hospital achieved more than $400,000 in calculated annual savings from the program. Expectations were exceeded when the organization saw significant, measurable energy reductions, double the originally projected, and a short-term payback within seven months.

From Strategy to Results

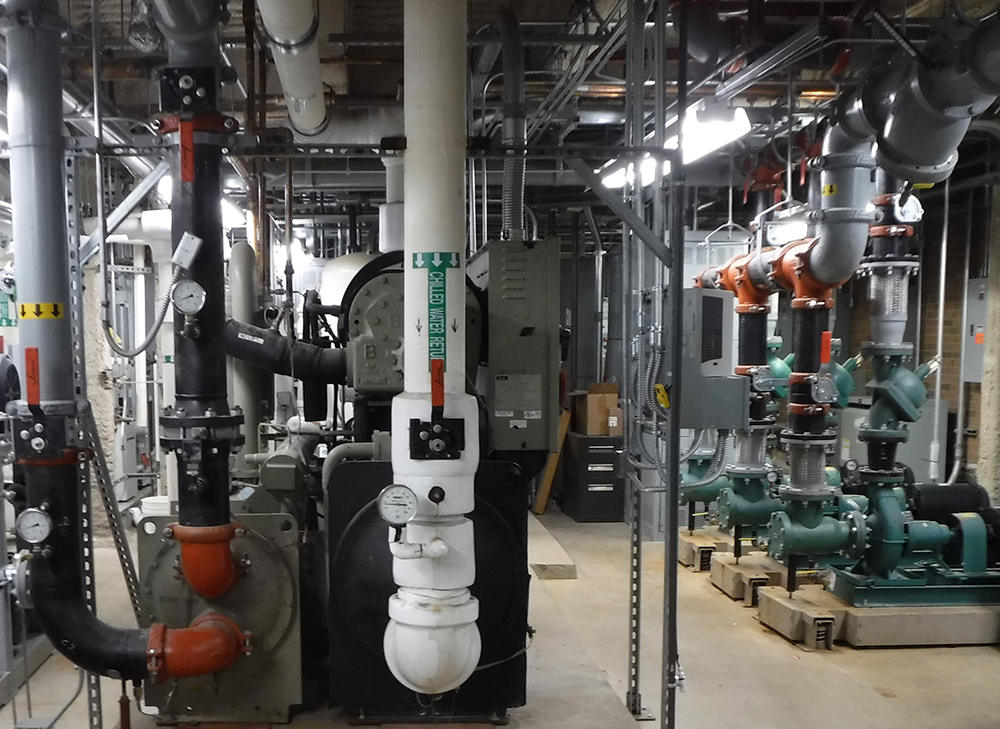

With a complex mix of legacy and modern systems, reflecting multiple expansions since the facility’s original construction in 1956, our client required a targeted approach to identify cost-effective energy conservation opportunities that would not disrupt critical hospital operations.

EH&E conducted a comprehensive energy-optimization study and collaborated closely with the client’s staff, performing onsite assessments and system performance analyses. This work identified key opportunities to optimize HVAC operations, improve controls, and repair underperforming components to enhance both energy efficiency and comfort.

By implementing various Energy Conservation Measures (ECMs), our client significantly improved the efficiency of its mechanical systems and reduced its energy footprint. The project progressed through multiple phases: Study, Analysis, Implementation, and Verification, with an additional implementation phase added to address interdependencies among identified ECMs.

Beyond the measurable reductions in energy use and cost, the project established a strong foundation for continued optimization, enabling the hospital to reinvest savings into patient care and facility enhancements.

Key Measures and Results

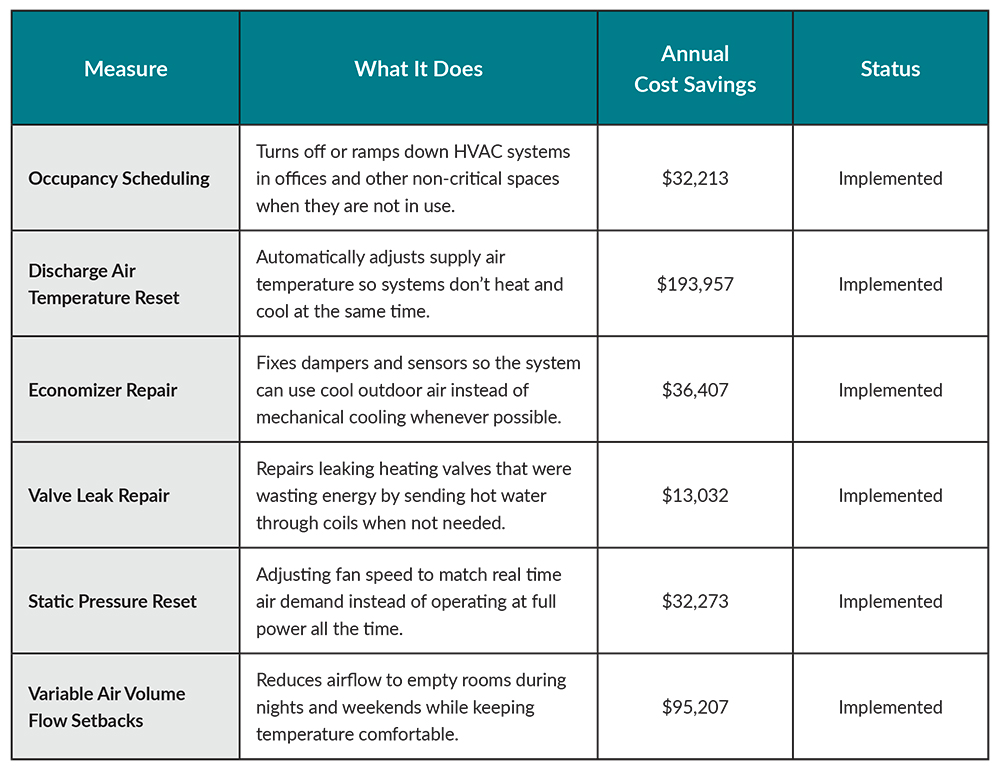

During the study and analysis phase, EH&E identified six high-impact ECMs. Each was evaluated for potential energy reduction, cost savings, and implementation feasibility. Together, the implemented measures deliver substantial operational and financial benefits for the hospital:

While the table above summarizes each measure and its savings, the results were achieved through careful sequencing, room-by-room system review, and close coordination with facility staff. The examples below take a closer look at several key measures and how and why they were implemented.

Occupancy Scheduling

Many hospitals assume HVAC systems must run 24/7 to maintain safe conditions, but not every space requires continuous operation. EH&E conducted a room-by-room analysis to determine which areas were served by each air-handling unit and identified administrative and non-critical spaces that were unoccupied after hours. By implementing occupancy-based scheduling, these systems now power down when not needed, cutting wasted energy while maintaining comfort and reliability in patient care areas. The change delivered about $32,000 in annual savings.

DAT Resets

Many hospitals’ air-handling units maintain the same supply air temperature year-round, regardless of outdoor conditions. EH&E adjusted these controls so discharge air temperature now responds to the weather, running warmer in mild conditions and cooler on hot days. This simple change eliminated simultaneous heating and cooling, reducing chiller and reheat use and saving about $194,000 per year.

VAV Flow Setbacks:

Hospitals often repurpose spaces and rooms, but ventilation settings don’t always keep up. EH&E’s assessment found several areas still controlled to exam-room standards despite being converted to non-clinical uses, and zones maintaining fixed airflow in both heating and cooling modes. After correcting static pressure, economizer, and discharge air temperature controls, EH&E adjusted VAV setpoints to match each space’s current use per ASHRAE and FGI guidelines. Air flow was reduced during steady and heating conditions, improving efficiency without affecting comfort, delivering over $95,000 in annual savings.

Looking Ahead

The hospital’s success demonstrates how data-driven energy optimization can deliver measurable savings without major capital investment. EH&E’s team helps hospitals and research facilities identify practical, low-risk opportunities to reduce energy use, improve system performance, and reinvest savings where they matter most. Learn how EH&E can help your facility achieve similar results.